Ethanol

Ethanol is its pure form can be quite expensive due to taxation. Denatured ethanol is cheaper but is not food grade due to the chemicals added to prevent human consumption(methanol, isopropanol, MIBK, jet fuel).

While some protocols call for the use of 200 proof, many times 190 proof or 95% ethanol can be used. For example, 95% ethanol is preferred for winterization because the small amount of water increases the polarity and in turn helps precipitate the very non-polar fats and waxes.

While some protocols call for the use of 200 proof, many times 190 proof or 95% ethanol can be used. For example, 95% ethanol is preferred for winterization because the small amount of water increases the polarity and in turn helps precipitate the very non-polar fats and waxes.

Some extractors also prefer to use 190 proof over 200 as their solvent. Pure ethanol can “lyse” cells, causing the membrane to burst. This is because pure ethanol is a harsh dehydrant and pulls water from the plant cells so quickly that the cell membrane bursts releasing DNA, chlorophyll, and other biologicals into the ethanol..

Recycling your ethanol that has accumulated water and other impurities can have tremendous savings. B/R distillation systems can recycle anything from 5L to 1000L.

Recycled alcohol should not have any color. The alcohol will be 99.9% pure but the concentration will be a maximum of 95% (190 proof). The recovery rate for alcohol is about 85% on average meaning you will still need to buy some alcohol.

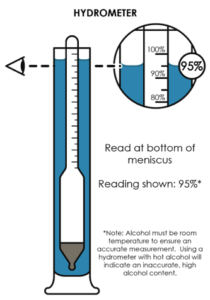

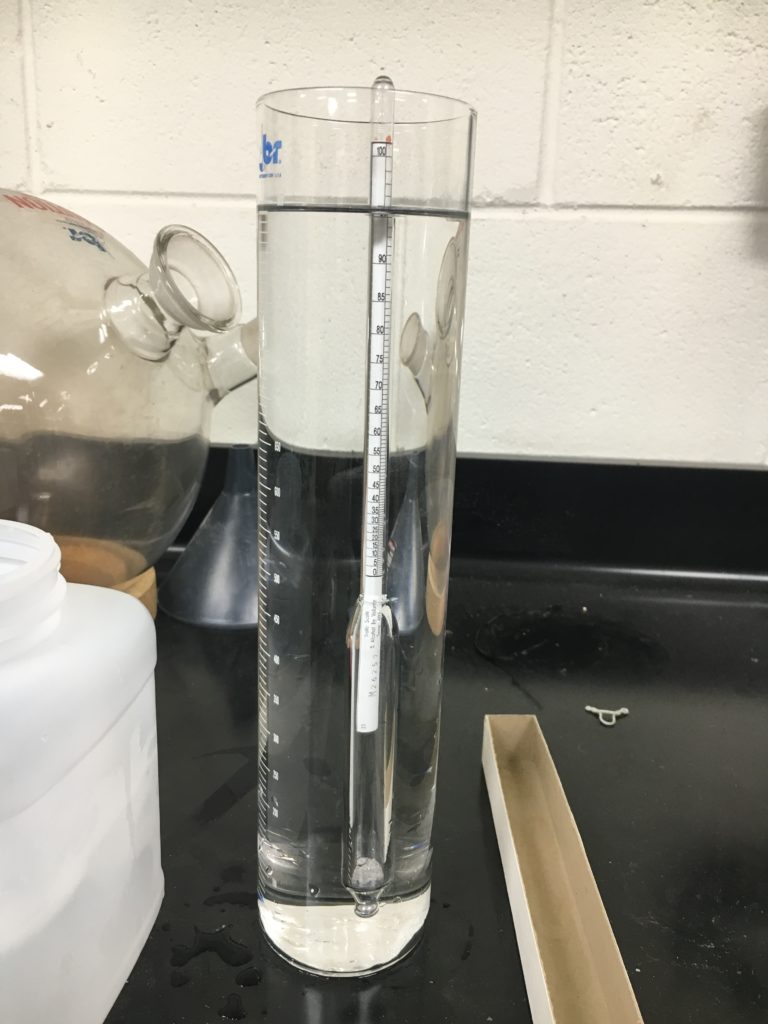

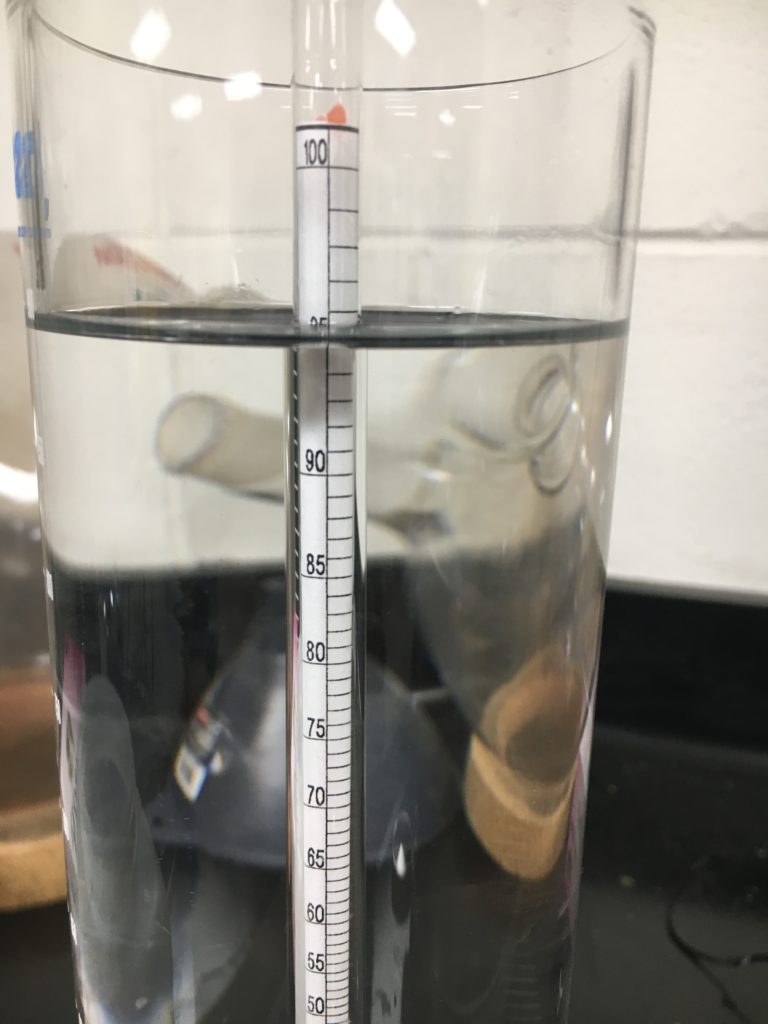

How to check purity with a hydrometer.

Make sure the hydrometer is floating freely. It should not touch the sides! The hydrometer will have a temperature that it was calibrated at on the packaging or with the instructions. For most accurate results, use only when the temperatures are close. The hydrometer in the photograph was calibrated to 15 °C.

Comments are closed, but trackbacks and pingbacks are open.