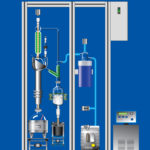

Micro Distillation of Crude Oil 7 to 100 ml

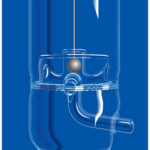

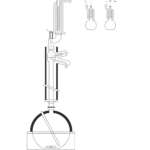

Very small amounts of crude oil (7 – 100 ml) can be distilled with the B/R micro crude oil distillation system. The spinning band with a maximum of 15 theoretical plates can collect a number of fractions with good separation. Spinning band has low hold up and very high free space. This makes spinning band […]