Reflux is the return of condensed distillation vapor to the boiling flask.

Reflux ratio is the ratio of the condensate returned to the boiling flask to the condensate being collected in the receiver. The reflux ratio is accomplished using a reflux valve in a “seat” over the take off point. When the reflux valve is raised up, condensate can pass through the seat and on to the receiver. When reflux valve is in the the down position, condensate flows over the spillway and back down the distillation column to the boiling flask.

Reflux ratio is the ratio of the condensate returned to the boiling flask to the condensate being collected in the receiver. The reflux ratio is accomplished using a reflux valve in a “seat” over the take off point. When the reflux valve is raised up, condensate can pass through the seat and on to the receiver. When reflux valve is in the the down position, condensate flows over the spillway and back down the distillation column to the boiling flask.

Reflux increases the vapor-liquid contact between the rising vapor and the descending liquid. Increasing vapor-liquid contact improves the efficiency of the distillation. In other words, more vapor liquid contact give a better separation. Likewise, the higher the reflux ration, the better the separation.

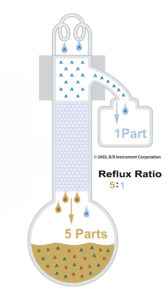

D2892 calls for a 5:1 reflux ratio. 5 parts of the condensate are returned to the boiling flask while 1 part is collected in the receiver.

This is true for the atmospheric and 100 mmHg vacuum sequences. For the lowest vacuum sequence (typically 10 mmHg) there is a choice between 5:1 and 2:1 reflux ratio. 5:1 remains the standard but if all parties agree 2:1 reflux ratio may be used.

Comments are closed, but trackbacks and pingbacks are open.